Brands are continually searching for components that not only lift the look of their products but also their performance with their packaging in the highly competitive perfume industry. With the PP Perfume Cap Luxury alternative, one of the most dependable, elegant, and flexible solutions has re-emerged for today's perfume makers. Made accurately and meant to give off a luxurious look, this type of closure offers the necessary durability, style, and ease of use for the high-end fragrance market of today. In fact, the PP Perfume Cap Luxury model is the one that raises the product price and helps in the formation of a refined brand image, be it a small niche perfumer or a giant cosmetics company.

The PP Perfume Cap Luxury shape is created from a top-notch polypropylene, a material that is generally known for its light but strong nature, its resistance to chemicals, and its ability to keep the structure intact even after prolonged use. The product is aimed at luxury fragrance bottles demanding the two aspects of the product, namely the beauty and the performance. Its face can be decorated using such methods as electroplating, spraying, metallic finishing, UV coating, hot stamping, and soft-touch matte. These give the perfume manufacturers the ability to get their caps in line with their general design theme, whether it be from simple yet elegant to shining metal and striking.

Apart from the style, the PP Perfume Cap Luxury part's framework is made to guarantee the closing is safe, the fitting is stable, and it is averted from spilling of the contents unintentionally. Moreover, the cap's design humanizes the grasp, enabling smooth opening to users, thus, making the sense of luxury more palpable with every use of the perfume bottle. As consumer demands become high, this cap alternative is perfect as it combines beauty with efficiency.

The greatest asset of the PP Perfume Cap Luxury product is its strong polypropylene material. PP has very good resistance to impacts, which means that the cap can be subjected to a drop, shaken during transportation, or even be handled among the daily event, and still, it will not crack or take on a permanent deformation. Besides that, it is also immune to alcohol and oil-based perfume formulations, thus, a long service life is guaranteed while the bottle's neat professional look is retained. This ruggedness is what really allows the perfume brand to be seen as a luxurious one.

With the PP Perfume Cap Luxury unit, customization is carried to the next level without limits. The brand may opt for one of the following finishes for a metal electroplating: gloss or matte, color gradient transition, soft-touch, and an embossed or debossed logo. The different methods of customization serve the brand identification purpose and also act as a unique feature that sets the perfume line apart from others that are placed on the shelf at a retail shop. Moreover, with the consumers progressively valuing packaging as an art, this cap type is a medium through which the brand can provide the customer with a premium unboxing experience and thus perceived product value gets elevated.

High performance is what makes the most costly fragrances valuable. There is a tightly fitting internal mechanism that has been engineered with precision in the PP Perfume Cap Luxury design which when combined with the sprayer neck achieves the closest possible fit thus sealing is ensured. As a result, this assures safe use without any emission of volatile compounds even during cross-border transportation or the retail distribution stages which might be far away from the point of origin. Therefore, brands can have the most conclusive assurance regarding fragrance quality, thus, the absence of the multi-directional issues such as evaporation, leakage, and loose closures.

While the PP Perfume Cap Luxury idea may look luxurious, it is still quite a light construction. As a result, it diminishes the cost of the transport, increases the user's comfort, and is a bona fide environmentally friendly alternative to a heavier metal cap. The PP used is recyclable which is in line with the sustainability developments modern-day beauty brands are pursuing. So, here is a cap that combines luxury aesthetics with eco-friendly designing principles.

If we compare the PP Perfume Cap Luxury to the ones produced of aluminum or zinc alloy, then the option of the second one, i.e. plastic, gives the most excellent ratio of price to performance. On one hand, manufacturers can use the latest surface finishing techniques to come up with a visually appealing product of high quality. On the other hand, they would still be very cost-efficient. This benefit turns the closure into a bathing suit capable of both major-market perfume and niche fragrance industry players.

The PP Perfume Cap Luxury design can satisfy the needs in fragrance packaging, which are diverse, such as:

Thanks to its flexibility, the PP Perfume Cap Luxury part can be utilized in various product lines, be it timeless floral scents or niche artisanal perfumes with a contemporary twist.

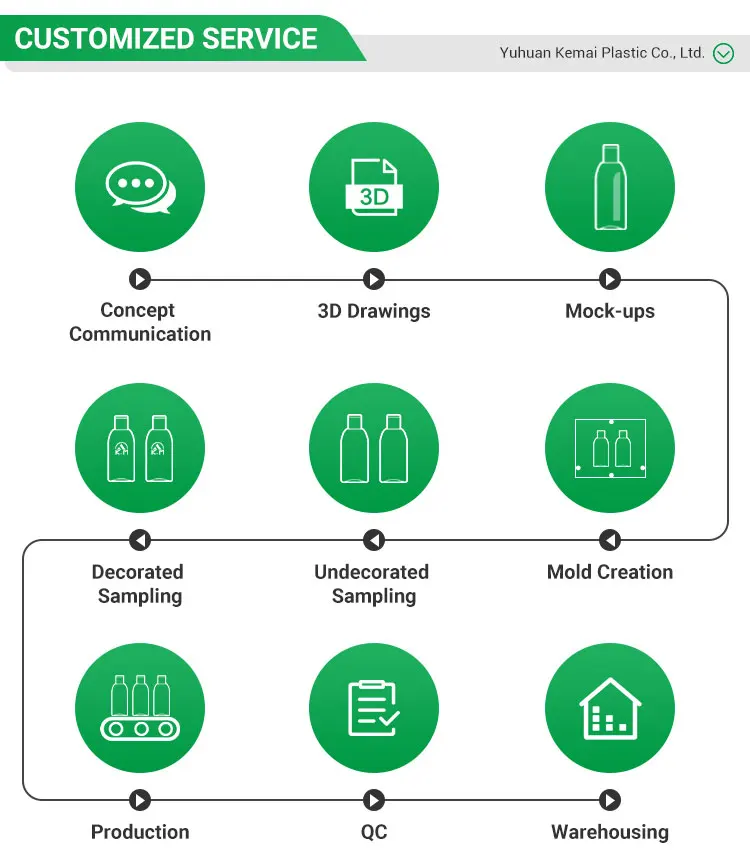

Quality that is the same from batch to batch is what is assured through the well-monitored and standardized production process the PP Perfume Cap Luxury undergoes. The manufacturing workflow is outlined in the sequential stages below:

The PP resin of the highest quality that is to be used for the production of the final product is first of all sourced and then inspected for purity and stability. Next, the raw material is dried and readied for molding.

The PP resin is forced into the highly precise molds under the influence of controlled heat and pressure. As a result of this step, the products have smooth surfaces, accurate dimensions, and they are of a stable structure.

The manufacture of the items is depending on the customization desired that is the reason for the factory having different departments for electroplating, spraying, UV coating, hot stamping, or logo embossing. The robots are used for a uniformity and consistency of each piece made.

The thoroughness and correctness of the dimensions, color, and sheen are verified. The degree to which the inner locking structure is tested for sealing is also determined.

Cap parts that have been completed are mated with the inners and, after being wrapped in anti-scratch protective materials, are made ready for the return journey to the manufacturers of the fragrance industry.

The system in place for this manufacture is what makes the PP Perfume Cap Luxury capable of meeting world quality standards.

To keep the PP Perfume Cap Luxury part working at its best, the below instructions would be of help:

It is by performing these simple tasks that the PP Perfume Cap Luxury product's working and visual feature will stay unspoiled during a complete period of use.

Place of Origin |

China |

Zhejiang |

|

Brand Name |

KEMAI |

Industrial Use |

Cosmetic bottle packaging |

Plastic Type |

PS+PP |

Shape |

Unique |

Color |

customizable |

Logo |

Custermized |

OEM/ODM |

Acceptble |

Payment |

T/T 30% |

MOQ |

10000pcs |

Refillable Empty Containers Flip Lid Travel 30 50 60 100 ml Plastic Squeeze Bottles With Keychain Hook

Customizable 1.65L PC Handle Straw Plastic Bottle PETG 2.2L Fitness Workout Sports Water Bottle

200ml 300ml 500ml Fine Mist Cosmetic Sprayer for Lotion Perfume Refillable High Quality Continuous Spray Trigger PET Bottle

Eco Friendly 350ml 500ml Leak Proof Durable Small Bear Design PET Plastic Bottle for Juice Honey Storage